AMPIN is expanding into powering data centers and renewable manufacturing, with its Odisha gigafactory set to produce 2 GW of cells and 1.5 GW of modules.

Tariffs are climbing amid import curbs, the end of full transmission-charge waivers and policies like ALCM/ALMM, though lower GST on solar components could soften the blow.

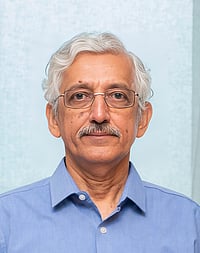

Pinaki Bhattacharya urges stronger government backing and viability-gap funding to scale up emerging clean-energy technologies like offshore wind.

He argues non-tariff barriers like ALCM should exclude private C&I players, calling for more pragmatic, phased policy rollout.

AMPIN Energy Transition, a renewable energy company backed by global institutional and impact investors including LGT Lightrock, Asian Infrastructure Investment Bank, Sumitomo Mitsui Banking Corporation and Siemens Financial Services, has commissioned a 50MW solar plant in Bemetara district, Chhattisgarh, marking its first open-access solar project in eastern India. With a 5GW portfolio and plans to double capacity to 10GW by 2030, the company is now moving into green hydrogen, energy storage and solar manufacturing, while adding data centres to its client base.

In an interview with Outlook Business, Pinaki Bhattacharyya, the company’s founder, MD and CEO, discusses its diversification strategy and calls for stronger government engagement to accelerate the energy transition.

AMPIN is providing power to Nxtra by Airtel, Amazon Web Services and Hewlett Packard. With the rapid rise of AI and data centres, do you see your business strategy shifting further towards powering data centres?

Data centers are a major growth opportunity for us, and we are already active in this space. With data center growth, we will also expand. But, at the same time, sectors like cement and steel also represent huge opportunities. Heavy industries require enormous amounts of power, whether it’s for producing steel or manufacturing cement.

Your upcoming gigafactory for cells and modules in Odisha, set up in partnership with Jupiter International, is expected to start operations next year. How will you ensure your components remain competitive on both technology and cost?

We have chosen technology and equipment that deliver the best outcomes. For example, some of the core cell technology comes from Germany, while other components are sourced from China and other parts of the world. These are tried and tested technologies that ensure optimal output.

Jupiter will bring deep manufacturing expertise, while we contribute financing, market knowledge and our in-house team. From a financial standpoint, we are structured to remain cost competitive. The project’s proximity to a port also adds logistical advantages, further strengthening efficiency. In a couple of years, the manufacturing capacity should reach at least 2 GW of cells and 1.5 GW of modules.

Anyway, we are not facing competition from China, as cells and modules cannot be imported after June next year.

Since imports of cells and modules from China will be barred from next year, the costs for developers could go up. How do you view this concern?

Yes, costs have definitely increased, and that translates into higher electricity prices. Module costs have gone up, which could increase tariffs by almost 25–30 paise.

In the commercial and industrial (C&I) space, however, even with a 30–35 paisa increase in tariffs, customers are still saving at least 30% on their overall costs. So, the business remains viable, but customers will need to adjust to paying slightly more.

There will be a market correction. Overall tariffs in the C&I space, and even in utility bidding, will need to rise next year. Ultimately, the government also has to accept that the policy change may involve buying more expensive power.

Apart from the manufacturing plant in Odisha, are you planning more facilities in India?

Yes, we are planning additional facilities, including cell and storage manufacturing in eastern India. Our manufacturing focus will be on three areas: cells, modules, and storage. We will announce further expansions only after the first plant becomes operational.

What policy changes do you expect from the government to make the energy transition much faster?

One important change is that we should not have non-tariff barriers. Ultimately, the economics should prevail. I believe there should be a gradual implementation of ALCM [approved list of cell manufacturers]. It should not apply to the C&I sector. Forcing one private party to buy cells from certain companies is not practical. The private sector should be kept outside the purview of ALCM. Instead, ALCM can apply to the government sector, where bids are enabled through discoms. That would at least provide some relief.

How will tariffs be impacted by the expiry of 100% waiver on inter-state transmission system (ISTS) charges for renewable projects?

The delivered cost of power to the end customer has increased. Still, it is manageable. Ideally, the government should have deferred this by a year because we already lost two years due to Covid-19 pandemic, and on top of that, there are many issues. Transmission capacity has not come up on time. Although there is a mechanism that allows waivers to continue if the delay is due to transmission not being ready on time or force majeure, it has not solved the issue completely. A committee has been set up to handle such projects, but still, deferrals have not been granted.

As a result, everything being done is increasing the cost of electricity. Waivers are not being extended, and sometimes transmission lines are not available when required. For instance, you may build a power plant, but evacuation gets delayed by six months. On top of this, policies like ALCM and ALMM are also pushing up costs.

Now, GST reduction will help ease this burden by offsetting some cost increases, thereby supporting wider adoption of renewable energy, green hydrogen and energy storage.

The government wants us to go green, and we are doing that, yet there were taxes along with expectations of no rise in tariffs. But next year, tariffs in both the C&I and utility segments will go up. The times have changed: tariffs were dropping earlier, but now they have started rising, and they will continue to rise. Even then, projects will remain viable. The savings may be lower, but savings will still be there.

AMPIN Energy Transition has also entered the green hydrogen space. How are you addressing offtake risks and infrastructure challenges in this area?

We are working on distributed green hydrogen solutions. For industries like steel, petrochemicals or fertilizers that require green hydrogen or ammonia, we plan to produce it directly on-site. If a steel company needs hydrogen, we will provide the electrolyzer to produce it and then supply the hydrogen directly at the plant. This eliminates offtake risk since the hydrogen is consumed at the point of production. There is no need for liquefaction, transportation or uncertainty about buyers, similar to behind-the-metre solar projects.

To support this, we have signed an MoU with Air Water of Japan, and we will soon roll out green hydrogen projects. This will be an added-value product offered to our steel, petrochemical, fertilizer and even glass industry customers.

What role do you see floating solar playing in India’s renewable energy mix, and how are you tapping into the emerging opportunity?

There is massive opportunity, and we have perfected the technology. Although floating solar is not yet as large as other segments, it has started gaining momentum.

AMPIN, along with NHDC and SJVN won the first major floating solar project of about 300 MW capacity in Omkareshwar dam and commissioned its 140 MWp project, the first IPP to do so.

The cost of electricity from floating solar is slightly higher, but it remains profitable. With this proof of concept completed, many states and the central government are now coming up with more floating solar opportunities.

We are also seeing interest from industries. Some C&I players have water bodies within their factories that can host floating solar. The technology is stable and scalable. Eastern states with abundant water bodies offer significant potential for further expansion.

What kind of policy and financial support do you believe is essential for offshore wind to become viable in India?

Offshore wind is currently too expensive for India. If more expensive power is offered, customers simply won’t buy it, unless the government steps in. If offshore wind, which has huge potential, is to take off, the government must provide financial support. Otherwise, the private sector has no incentive to invest in projects that are too costly and not properly compensated.

Government must channel some of the revenue from GST collection into viability gap funding for offshore wind. While the government is auctioning rights, that alone isn’t enough.

Same is the case for pumped hydro storage. Anything that is not yet viable should receive support. Duties and taxes collected from the sector should be reinvested into the areas needing viability gap funding (VGF).

Even in cell and module manufacturing, we are getting production-linked incentives, but the support could be better. For example, cheaper power, better interest rates and special funding should be provided. China does that, which is why their cost of production is lower. In India, everything is left to private enterprises.

There is no government-owned solar cell or module factory in India. If the goal is complete independence from China, the government should set up a 10GW-scale large polysilicon and wafer manufacturing facility.

When the conventional power sector grew, the government played an active role. BHEL [Bharat Heavy Electricals] produced gas turbines, steam turbines and boilers, alongside competition from ABB, Siemens, GE and later Chinese companies. There was always at least one government organisation producing equipment. That model ensured pricing control.

When Siemens Gamesa's wind turbine factory was up for sale, a government entity like BHEL could have acquired it. With government participation, pricing would be more controlled and competition healthier.

Some PSUs are already efficient such as NTPC. If the government invests, it can make others like BHEL more efficient too and even create a technology leader in renewables. “Make in India” should not mean only the private sector manufactures. It should also include the public sector.

However, the government has been responsive. We are able to meet them regularly through industry bodies and advocacy groups. Beyond that, they also need to accelerate investments and direct participation in this space.

You are planning to expand to 10 GW in solar and wind. Given the many challenges in the industry, how confident are you about achieving your target by 2030?

Currently, we have a portfolio of 5 GWp, and we know it will keep growing. This transition is larger than even past tech revolutions. Our entire energy supply is changing. Over time, our C&I segment, utility-scale projects and manufacturing capacity will reach 5GW each.

In addition, we are looking at creating an investment management business INVIT [infrastructure investment trust], which will serve as an acquisition engine and investment asset. That too will scale to 5 GW. So, we envision a 20 GW potential by 2030 for AMPIN Energy Transition.

One challenge is that ISTS capacity has not ramped up in line with generation growth. However, we are in a relatively good position because we have secured substations for our projects.

On the C&I side, which primarily depends on STU [state transmission utility] projects, state-level transmission capacity is still available but underutilised. Because our strategy spans both state and central levels, we can maximize state-level transmission while central capacity catches up.

Because of our business diversification, we are well positioned. We are also active behind the meter. At the same time, we are pushing authorities to accelerate infrastructure development so the system can support faster growth.