India’s automobile industry could cut its manufacturing emissions by 87% by 2050 through making a shift to green electricity and low-carbon steel, says a study published by the Council on Energy, Environment and Water (CEEW) on Wednesday.

According to the study, if both OEMs and their suppliers were to aim for net-zero by 2050, annual emissions could fall from the projected 64 MtCO₂ (business as usual scenario) to 9 MtCO₂, an 87% reduction. “This would require OEMs to shift to 100 per cent green electricity,” the study says. Steel suppliers would need to use 56% hydrogen-based energy, reducing coal’s share to under 10%. In addition, increasing scrap-based steel production to 48% by 2050 would significantly reduce emissions and resource intensity.

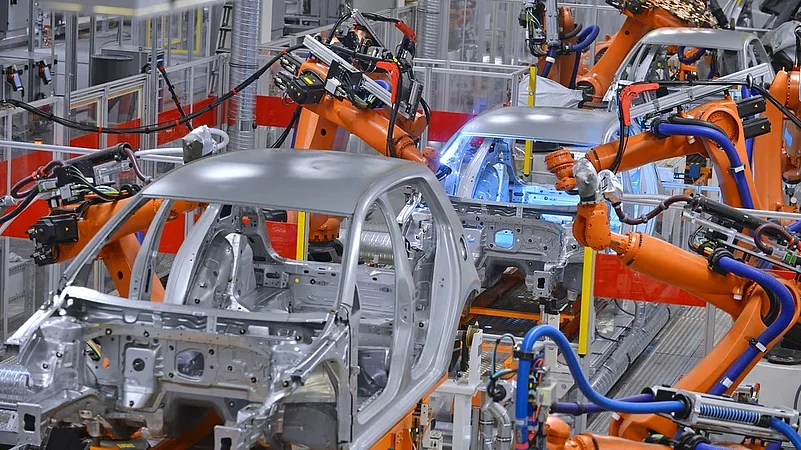

While leading OEMs in India have set ambitious targets to reduce direct factory emissions and downstream use-phase emissions, upstream supply chain emissions remain largely overlooked, the climate think tank said. Upstream supply chain emissions are a major contributor of the automobile sector’s carbon footprint.

“India’s auto industry stands at a turning point. To lead in a low-carbon global economy, we must decarbonise not just the vehicles we drive but the industrial processes that build them. Automakers must clean up how their vehicles are made, what powers their factories, and how their suppliers produce critical inputs like steel and rubber,” said Dr Arunabha Ghosh, CEO of CEEW.

The CEEW study tracked emissions across three scopes: direct emissions from vehicle manufacturing (Scope 1), indirect emissions from electricity use (Scope 2), and upstream supply chain emissions (Scope 3). Scope 3 emissions currently make up over 83% of India’s auto industry emissions, largely due to the use of coal-intensive steel and rubber in vehicle manufacturing.

“To align India’s automobile sector—central to GDP, jobs, and industrial growth—with a net-zero future, we must go beyond electrifying vehicles. We must decarbonise manufacturing itself,” said Dr Vaibhav Chaturvedi, Senior Fellow at CEEW and one of the author of the report.

The study recommends accelerating transition to EVs and decarbonising the full manufacturing value chain. Amid the debate of hybrids versus EVs, it examined a high-hybrid scenario where hybrids dominate in the near term before EVs take off. While this would reduce energy demand among component suppliers by 7%, emissions would remain slightly higher than in a BAU shift to EVs due to continued reliance on combustion engines.

“Since 65–80 per cent of a vehicle’s lifetime emissions come from its use phase, shifting to EVs remains the most effective way to cut end-use emissions. But deep reductions will only be possible if EVs are manufactured using clean energy and low-carbon materials,” it says.