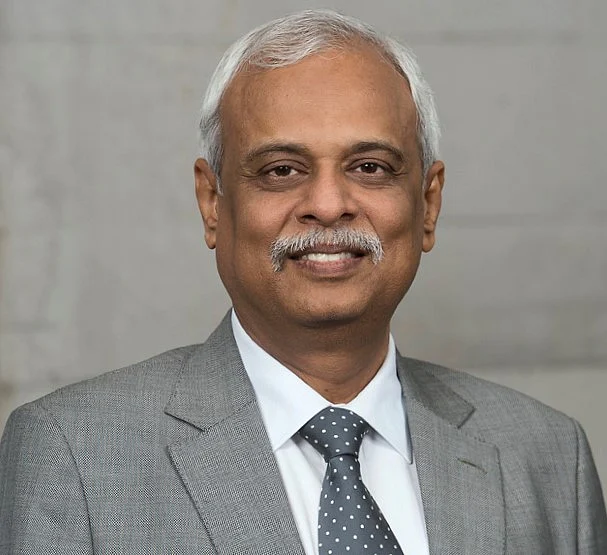

K. Balasubramaniam told Outlook Business that while democracy provides the framework, real economic progress comes only from strong industrial investment and execution.

He argued that India must shift its focus from policy talk to on-ground manufacturing capability if it wants to compete with global production hubs.

Balasubramaniam highlighted that companies like Tsugami India are expanding because Tamil Nadu offers a stable ecosystem, skilled labour, and predictable industrial policies.

He stressed that precision manufacturing will be central to India’s future growth, but only if the country prioritises technology upgrades, vocational training, and long-term industrial planning.

It is frustrating to compare China’s efficiency with that of India’s, says K. Balasubramaniam, Founder, Tsugami Presicion, India and MD of Proteck Machinery. A veteran of the country’s machine-tools industry, he played a key role in bringing the legendary Japanese precision machine-tool maker Tsugami to India.

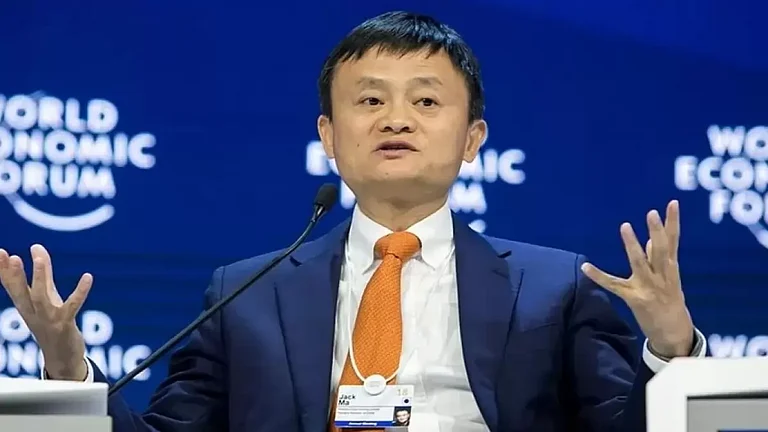

Balasubramaniam, who watched the machine tools industry in China from practically nothing to the world’s biggest, says it is difficult to compare the pace of growth or even the scale of China and India in this key sector.

“China can execute decisions without resistance. I’m frankly tired of people constantly comparing their efficiency to ours,” he said, adding that being a democracy, government bodies in India cannot take decisions quite as rapidly and decisively as in China.

Still, says the chairman & MD of Proteck Machinery, we are closing the gap with our northern neighbour fast enough to draw attention. “Many Chinese engineers were recently recalled not because India pushed them out, but because China is worried. That worry is good for us,” added Balasubramaniam, who currently serves as India Founder of Tsugami India.

Can you tell us how your association with Tsugami began?

Certainly. The focus tends to be only on Tsugami, but the story really begins with Protek and the company I founded back in 1985 after graduating from IIT Delhi. Protek was into precision manufacturing for printing, packaging and machine tools. Through that work, we began collaborating with Tsugami as their sales partner in India. In 2009, the chairman of Tsugami Japan approached me about starting manufacturing in India. Honestly, I was sceptical at the time, but his vision was far ahead of mine. That’s how Tsugami India was formed as a joint venture between Tsugami Japan and Protek.

How involved are you today in running Tsugami India?

I’ve been involved since the inception: first as managing director, then chairman. Today, I serve as executive advisor. In typical Japanese style, you retire, but they don’t let you retire. It’s the perfect role because I have influence without the day-to-day burden of responsibility.

How did Tsugami India’s manufacturing journey begin?

When we incorporated Tsugami Precision Engineering India Private Limited, our first factory actually started inside Protek’s 20-acre campus. That plant is still operating, as we gradually shift to the new one that was inaugurated today. Over time, we expanded from machines to a foundry and now a full assembly plant, both launched today.

What level of investment has gone into this project?

The commitment of Tsugami Japan has been extraordinary. There’s essentially no upper limit to how much they will invest long term. As of today, the investment is around ₹300 crore. Our initial capital was roughly ₹45 crore, and Protek is a minority partner because the scale of their [Tsugami’s] commitment is enormous.

What is the current production capacity and where is it headed?

Right now, from our older facilities, we produce about 130 machines a month. With the new facility added, our installed capacity rises to around 350-400 machines per month, depending on the product mix. Realistically, we expect to hit around 300 machines per month in the next two years.

Who are your major customers?

Tsugami machines cater to practically every manufacturing sector like automotive, medical, aerospace, electronics and everyone except defence. For example, Apple’s factory in China alone uses over 4,000 Tsugami machines. High-precision components for phones, tablets, laptops, connectors, solar components are all made on our machines.

With Chennai emerging as an electronics hub, what opportunities do you see here?

The potential is massive, and it’s already materialising. Chennai has a unique history because of the old Nokia ecosystem. Their tier-1 vendors stayed, the skilled labour force returned, and today many top Apple vendors are concentrated here. For a machine tool company, this location gives us a greater advantage than even Bangalore.

How do you compare Tsugami India to other global plants?

Tsugami has three plants in China and, of course, the parent plant in Japan. The Chinese facilities are almost ten times our scale. This year, we expect to reach [an output of] around 4,000 machines. If the market stays strong, we aim for a CAGR of at least 15%, far above the current industry average.

How does India compare globally in machine tool manufacturing?

Indian manufacturers still import CNC control systems like [those of] Siemens and FANUC mainly because there’s no indigenous equivalent. Major domestic machine tool players include Ace Micromatic, Jyoti, LMW and a few others. The Indian market is around ₹18,000-20,000 crore annually. Imports have steadily declined as domestic capability has grown. Among Japanese players in India, Tsugami has made, by far, the largest and clearest long-term commitment.

Apart from electronics, which other sectors rely heavily on your machines?

Medical devices are a big one, with dental implants, components for infusion pumps, and various high-precision parts used in hospitals. Aerospace is another major sector. We also supply to many Indian firms who produce components for Boeing and Airbus under offset clauses. There’s been a noticeable boom in civil aerospace manufacturing.

You’ve seen China’s scale up close. Can India realistically catch up?

Let me be blunt. Unless there is a radical shift in who we are, we cannot catch up with China’s speed. We are constrained by many things, and one of them and this is controversial but true, is democracy itself. China can execute decisions without resistance. I’m frankly tired of people constantly comparing their efficiency to ours. But having said that, I’ve seen real change here in the last 10-15 years, which is why I still work. We may not match China immediately, but we will close the gap. If we were one-tenth of China earlier, our next target is to be one-fourth.

Is China’s dominance weakening in ways that benefit India?

Absolutely. China has become increasingly non-cooperative in certain supply chains, creating hurdles even for global companies. Many Chinese engineers were recently recalled not because India pushed them out, but because China is worried. That worry is good for us. It means we’re doing something right, and global companies are shifting production here.

What made Tsugami Japan trust India so deeply and invest so aggressively?

I once asked the chairman this myself. He told me that in 2009, he saw India as being 20 years behind China and therefore destined to follow the same growth path. He had immense faith that India would rise. Tsugami is a legendary company in Japan, extremely profitable when many bigger firms are struggling. Researchers at Tokyo University have even studied their business philosophy. Their trust in India has been consistent, and after decades of working with the Japanese, I can say this with confidence: they may complain about many things, but their trust in us is solid.