India needs its own semiconductor fabrication units, as reliance on external fabs poses risks to national security and increases vulnerability in the global supply chain, said Veezhinathan Kamakoti, Director of IIT Madras.

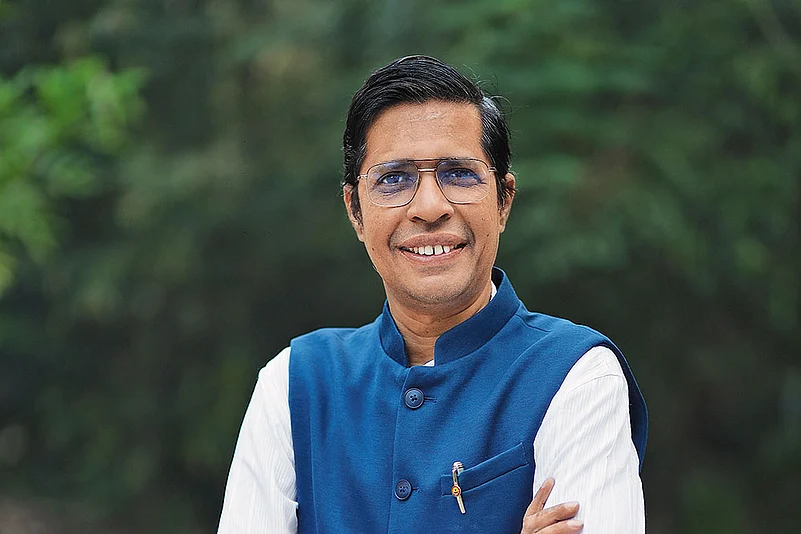

In an interview with Outlook Business, he discussed the vision behind ‘Shakti,’ the indigenous semiconductor chip, and highlighted the gaps in India’s approach that must be addressed to achieve key technological milestones.

Edited Excerpts:

Tell us about the indigenous ‘Shakti’ semiconductor chip and its evolution. Based on your experience, what are the key gaps in the overall process that need to be addressed?

The idea of using this microprocessor was conceived in Trivandrum, leading to the development of the Shakti microprocessor, in which I have been involved. We are currently working on the second and third versions. The Digital India Space Symposium is showcasing significant advancements in microprocessor development, with a major focus on IIT Madras.

This microprocessor was designed at IIT Madras, fabricated at SCL, and packaged at a Tata facility in Karnataka. The motherboard was also designed at IIT Madras, fabricated at PCB Power in Gujarat, and then returned for assembly at IIT Madras. Additionally, another company, Zema, based in Chennai, contributed to the process. Finally, the software was designed and refined at IIT Madras.

Given India's strength in chip design but limited fab facilities, should we focus more on design leadership rather than fabrication?

India must recognise the necessity of having its own semiconductor fabrication facilities, as relying on foreign fabs poses significant risks. While we excel in chip design, our dependence on external fabs means we may not receive priority treatment, especially when larger customers place bulk, long-term orders. This dependency could limit our access to critical technology, making us vulnerable in global supply chains.

The initiative by the Tata Group to develop a 28 nanometer (nm) fab is a step in the right direction. Additionally, upgrading the Semiconductor Laboratory (SCL) from 180 nm to more advanced nodes like 90nm or even 45nm is crucial for enhancing our capabilities.

From a national security perspective, importing chips means we can verify whether they perform their intended functions, but we cannot be certain that they don’t have hidden functionalities or vulnerabilities. Without full control over fabrication, we risk using black-box components with unknown security implications. This underscores the urgent need for indigenous semiconductor manufacturing to ensure both technological self-reliance and national security.

The exodus of high-tech talent has been a significant challenge for India for many years. How do you think this will impact a country with such ambitious aspirations?

In the past, discussions often centered around brain drain, but today, it has transformed into a brain game. Many Indian professionals who have gained valuable experience in cutting-edge technologies abroad are now eager to return and contribute to the country's growth. This reverse brain drain is crucial, especially in critical emerging fields like semiconductors and fabrication.

Several experienced individuals have already volunteered to bring their expertise back to India, motivated by a strong desire to serve the nation. Their global exposure helps accelerate our progress by bridging the knowledge gap in high-tech industries.

Furthermore, multinational corporations (MNCs) play a significant role in the semiconductor industry, particularly in designing complex chips like server processors. Indian engineers working in these MNCs gain hands-on experience with sophisticated design processes, learning the intricacies of the field in a well-structured environment. This exposure enables them to return with deep industry insights, helping India build a strong semiconductor ecosystem without having to start from scratch.

Harnessing this talent pool is a vital part of India’s journey toward technological self-reliance.

Defense startups in India are primarily focused on manufacturing indigenous products. Do you think they should explore other ideas as well? How can the sector grow in numbers to meet the increasing need for indigenous defense solutions?

The challenges in India today are quite significant. However, I strongly believe that if you solve a problem in India, for India, you are effectively solving it for the entire world.

A great example of this is vaccines. If we had imported vaccines, each shot would have cost around Rs 10,000 and required storage at 5°C, demanding extensive refrigeration infrastructure. Instead, we developed our own vaccine, which worked exceptionally well—evident in the fact that we are all speaking today without masks. Not only did we vaccinate our own population, but we also provided vaccines to other countries for free. Same goes with the defence sector.

Today, people around the world are looking to India for innovation. If you observe the startup ecosystem, many solutions are increasingly Indianised, designed specifically for our conditions.

Once a problem is solved for India, only minor tweaks are needed to adapt it for global use.

This is why I strongly encourage innovators to focus on solving India's problems—because in doing so, they create solutions with universal relevance.