Can a Tile Change the World?

Tejas Sidnal, Founder of Carbon Craft, a Karnataka-based startup, is on a mission to create carbon-negative tiles and building materials by harvesting pollution and industrial waste.

Building materials and construction processes are incredibly carbon-intensive, accounting for 11% of global carbon emissions. As the world's population nears 10 billion by 2050, this percentage is expected to rise sharply. This means that finding alternative building materials and processes is critical to decarbonising the building industry.

Tejas Sidnal founded Carbon Craft in 2016 with the aim of finding ways to turn buildings, which are currently polluting mechanisms, into carbon sinks. However, environmentally conscious buildings cannot exist without employing carbon-negative products. He has been working on upcycling carbon into building products since then.

Founder Tejas Sidnal

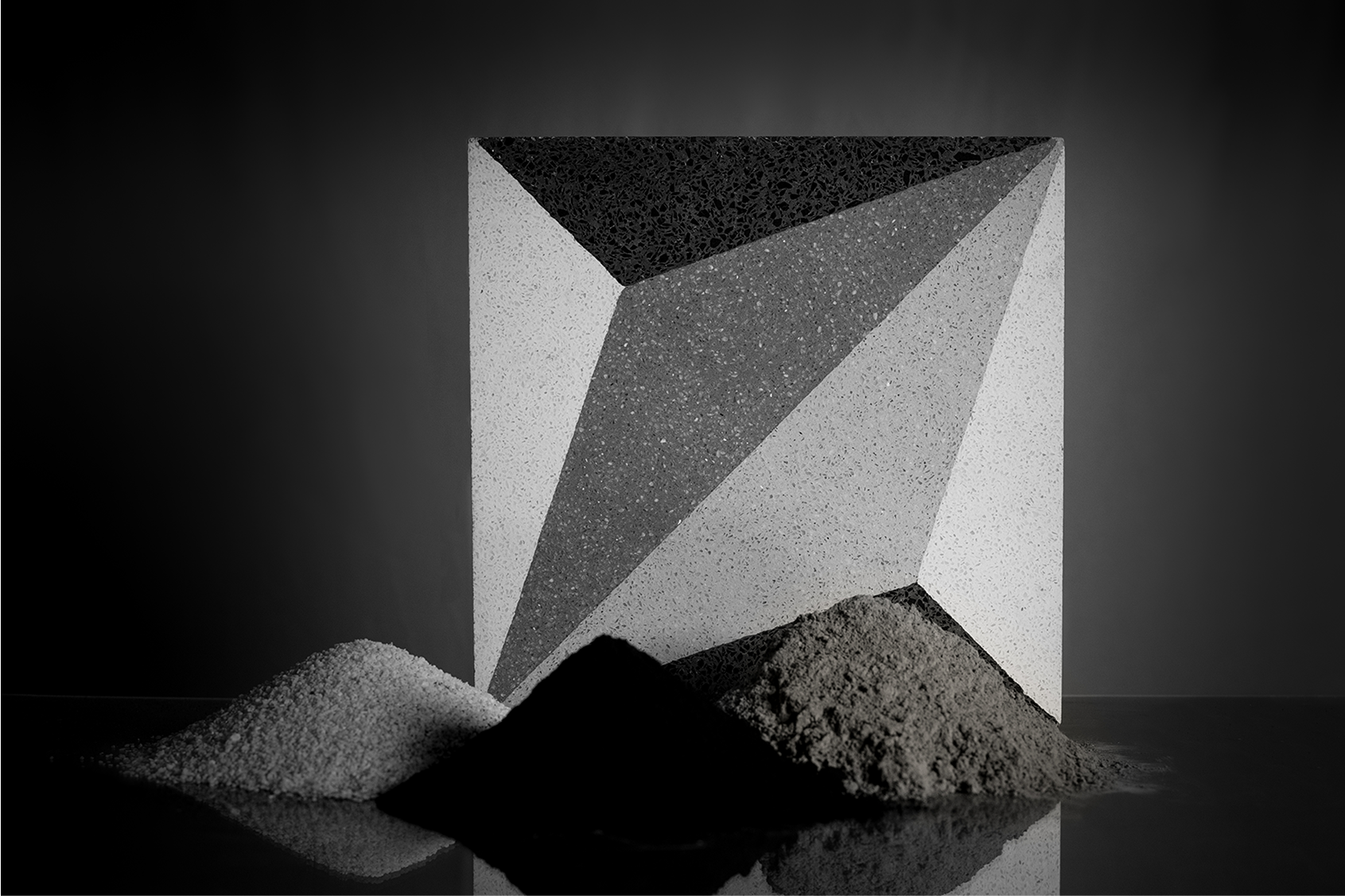

Carbon Tile

Image Courtesy of Carbon Craft

Having experimented with bricks, building facades, and other products using the captured air pollutant, Carbon Craft has pioneered the Carbon Tile. Apart from being low energy intensive, the tile has the advantages of being scalable and economically viable while offering diversity in design. The tile is made from a combination of recovered carbon black and construction and demolition waste, like marble chips, marble powder and other industrial waste that would otherwise end up in the landfill

The initial sources for the waste carbon as a raw material for the tile were the tailpipes of cars, which turned out to be a costly affair with the limitation of being difficult to scale. Carbon Craft then turned to the tyre industry — one of the biggest consumers of carbon black, which lends the tyre its black pigment and is obtained by burning fossil fuels in a controlled environment. The tyre will likely end up in the scrap yard and a recycling unit at the end of its life, where the recovered carbon black is generated — which on any normal day gets burned again, adding to environmental pollution. A paste of this recovered carbon black and other industrial waste is passed through a hydraulic press to create the Carbon Tile, which stores carbon equivalent to 5 kilograms of greenhouse gas emissions. This entire process consumes less energy than conventionally produced tiles while lending it enough strength to compete with leading tiles in the market.

The tile is also chosen to be handcrafted rather than machine-made so as to reduce its overall carbon footprint. This also allows flexibility and experimentation with designs to suit all aesthetics. Inspired by the unique identities of the cities and the natural elements that define them, the tile is designed to create a wide range of flooring patterns.