Tork Motorcycles might be camouflaged among the bigger units dotting the bylanes of the MIDC industrial cluster in Bhosari near Pune, but there’s no hiding the T6X — on course to become India’s first bike that runs on a 20-kg plus lithium-ion battery pack and deliver speeds upwards of 75 kmph. “Instead of being built ground-up, electric two wheelers in the country so far are just remakes of existing two-wheeler frames, patched with an electric motor,” says founder Kapil Shelke, who is trying to change this with the rugged, powerful beast. While its predecessor T4X could clock 0 to 100 kmph in less than nine seconds, Shelke is mum on the details of its sixth prototype. “It won’t be a letdown, but I can’t reveal much before the final tests,” he adds.

The bike, which can cover 100 km on a single charge, was born out of Shelke’s engineering project. “Our initial idea was to create an electric car but we couldn’t afford the budget. As I was always an avid biker, we felt we had a better chance of creating an electric bike,” says Shelke, who along with his friends, pooled in Rs.4 lakh to create TX01, which could clock over 150 kms an hour!

So taken were Shelke and his friend by the beast that they chose to skip their final year engineering exams to take part in the Mecca of motorcycle racing, the Isle of Man TT, in 2009. “We could give our exams next year but this racing event, the first to feature only electric bikes, was a once-in-a-lifetime chance to prove ourselves.” The gamble paid off. They ended up third in the race. But as his friends chose to move on, Shelke formed his own company and continued tinkering with the prototypes, even working with Chinese two-wheeler manufacturer Zongshen’s electric motorcycle racing team. In 2014, he stripped down a 150cc Yamaha FZ into an electric motorcycle and displayed it at an auto expo in Gujarat. “The accolades kept coming from dealers and buyers, who wanted to know how much did it cost. Since it was a prototype, they balked when I said it cost me over Rs.3.5 lakh,” chuckles Shelke, who decided that if indeed there was demand for a fast electric bike in the country, he had the engineering prowess to deliver it.

As luck would have it, he got to pitch his case before some angel investors and managed to raise seed capital from Ola founders Bhavish Aggarwal, Ankit Bhati and CoCubes co-founder Harpreet Grover. “Over the next couple of months, we should be ready with our production version of the T6X,” says Shelke. However, it will take some time before enthusiasts can own the bike, as Tork will have to raise fresh funds to mass produce.

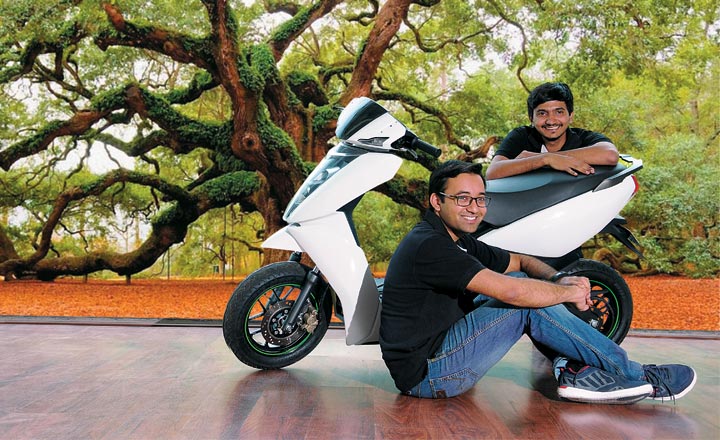

But even as Shelke and his 25-member team are putting the final touches to the prototype, two other engineering graduates from IIT Madras are emerging as the new poster boys in the electric two-wheeler space. Tarun Mehta and Swapnil Jain, with their 140-member team (comprising 110 engineers) have already built the country’s first smart electric scooter in Bangalore. What’s more? The three-year-old start-up expects to have over 10 patents for the entire vehicle.

Kick-start

Mehta, a native of Ahmedabad, and Jain, from Mumbai, were classmates at IIT-Madras. They graduated in 2012, with Mehta moving to Ashok Leyland and Jain joining General Motors. But fate had something else in store as the two did not take a fancy to their jobs and ended up knocking on the doors of their alma mater to pursue what they had started as an engineering project. “We had already worked on drivetrain components and felt why not build on that,” shares Mehta. The duo approached two-wheeler customers asking them, “What if we give specs that petrol scooters offer in an EV.” The answers were encouraging, but would people pay? In this case, it turned out to be affirmative. Mehta says, “We collected Rs.6 lakh upfront from 25 clients even before the prototype was ready.”

Things fell in place as IIT Madras incubated the start-up in November 2013. An alumnus Srini Srinivasan, co-founder of US-based Aerospike, which makes the fastest database used in real-time applications, too chipped in with funds. Commenting on why he chose to back the two, Srinivasan says, “Very rarely does a great leap forward in technology come from large companies. In India, the problem is worse than in other places since large manufacturers have zero interest in innovative solutions. They are merely assembling technology from outside as they lack innovative engineers. Ather is one of the many recent start-up ventures that I believe will change the status quo.”

Also helping the duo through their initial teething period was Professor R Krishna Kumar of the engineering design department of IIT-Madras. “What was impressive about them was that they were clear about what they wanted. The brief was clear from day one: The design has to be robust, suit Indian conditions and not be a cheap assembly of components from China.” The challenge before Ather, thus, was to build a zero-compromise electric scooter, which was as good as its petrol variant.

The biggest learning came from within the domestic EV space where manufacturers typically concentrate on the platform and not the end product. “Electric vehicles in India have not taken off because they are overpriced for the specs that they offer. Our biggest learning was that early adopters can’t compromise on any parameters. I cannot say it’s an electric scooter, hence, it cannot match its petrol counterpart — that’s a deal-breaker right from the word go,” says Mehta.

But to deliver on the promise, Ather had to build a team. That meant roping in automotive aficionados, who were in it for the passion and not just the pay. They found one in Arun Vinayak, a fellow IIT-Madras graduate, who quit his job at ITC to join Ather as the chief product officer. During his campus days, Vinayak was instrumental in building a Formula 1-type race car for an international competition in Germany. But the new task at hand had much more at stake.

Cracking it

As Ather kept building its team, the big kicker came when the Bansals of Flipkart and Raju Venkatraman of Medall Healthcare pumped in $1 million in December 2014. It set the ball rolling for Mehta and Jain.

While Ather had crystallised the look and basic specifications in the initial six months, the team spent a lot of time on thermal design, electronics and building the battery management system for the IP67-rated battery pack. IP67 rating means the battery is dust proof and can stay submerged in one metre of static water for half an hour. The battery pack is built on the 18650 cell format also used by Tesla Motors in its Model S electric car. The basic role of the BMS is to act like a smart switch, which prevents the battery from overcharging by monitoring the voltage and current at an individual cell level. It ensures that even after 1,000 charges the cells will be re-balanced and would not get weak and fail. The life of a lithium-ion battery is cut short if the cells are not balanced. “What we have on the S340 is the sixth version of the BMS,” says Vinayak. Unlike conventional electric vehicle batteries, Ather’s battery pack charges faster and can last more than 50,000 km, with a life span of close to seven years. In fast mode, the battery can charge up to 80% in an hour and three hours for a complete charge, in normal mode, consuming close to three units of power. More importantly, thanks to the 5kw motor, which is three times more powerful than the conventional motors seen in electric scooters, the S340 can do 0-60 kmph in 12 seconds, with a peak torque output of 14 Nm that’s atypical of 100-125 cc bikes.

Getting personal

Among the several firsts, the S340 will also sport a touchscreen digital dashboard, again completely designed in-house, with an on-board navigation system. While the OS of the dashboard — featuring a factory fitted 3G SIM card — is Linux-based, the navigation system will feature Google Maps. “The interface of Google Maps is something that everyone is comfortable with. So, that’s the base layer on which we will contextualise data about the driver. The vehicle will know what you like, what’s the weather, the most efficient route to reach the destination. Once you start using the vehicle through different routes, its intelligence response will keep getting better,” says Mehta. However, as a safety feature so that the driver doesn’t takes his eyes off the road, the touch function will not work when the scooter is in motion. Ather is, however, looking at a playback feature by incorporating a speaker on the dashboard to address the issue.

A mobile application will configure the ride based on individual profile and his riding habits. Over time, it will help the S340 to predict the distance it can cover based on the user’s riding pattern. “The scooter can even automatically optimise itself by reducing the acceleration and speed, thus ensuring the rider gets to reach home,” adds Vinayak. Not just riding patterns, the predictive analytics will also help the owner know which parts will need to be replaced over time and if there is any potential trouble in store. “The S340 with through remote diagnostics using sensors will predict which component is due for a replacement and after how many kilometres later will it need to get replaced or serviced,” mentions Mehta.

Ather is also banking on creating a rich history of data once the vehicles hit the road. “Over a period of time, it will help reduce the need for annual maintenance contracts and periodic vehicle check-ups as enough data will be at the vehicle owner’s hands. For us, the data would yield greater insights into further improving the product,” adds the co-founder.

Complete package

At 90 kg, the S340, whose body is made from acrylonitrile butadiene styrene lightweight plastic, is 15% lighter compared to a regular scooter. Ather has also managed to get a 49:51 weight distribution compared with 30:70 in a conventional scooter, making it a lot more stable and responsive. In the absence of an engine, there is 50% more storage space, enough to store two helmets. Instead of power-hungry halogen lamps, the S340 features energy efficient intuitive light-emitted diode lights, both at the front and rear, which will respond to ambient light conditions.

Barring the lithium-ion battery and motor, which are imported, a large number of components on the S340 have been indigenously-designed and manufactured with the help of local vendors, nearly 100 of them. “While standard components are being sourced from the regular tier-1 automotive vendors, cells, cooling compounds, the display, processors, are just some of the components where we are engaging with vendors who will be first-time suppliers in the Indian automotive space,” reveals Mehta.

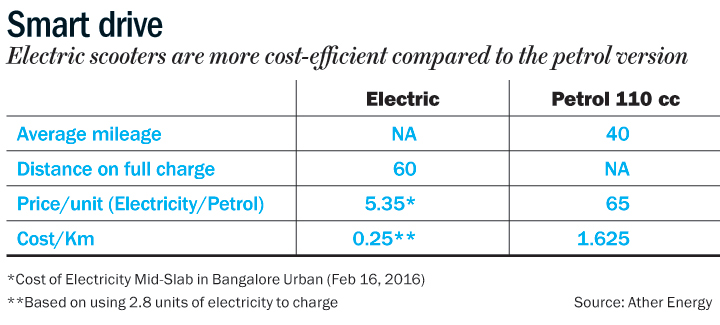

More importantly, with fewer moving components and faster charging time, the cost of ownership is expected be significantly lower vis-a-vis petrol scooters. “The cost of ownership works out to 25 paise per km for the S340, while it’s over a rupee for conventional two-wheelers,” adds the co-founder.

And barring the periodic checking of brake calipers, tyre tubes and other peripherals, there are no major costs that a customer has to worry about. “A petrol two-wheeler’s maintenance cost works out to Rs.10,000 to Rs.12,000 a year, depending on the model, whereas it will be around Rs.1,500-2,000 a year for the S340. The buyer will break-even in two to three years, depending on the mileage,” claims Mehta.

Last mile

Unlike Tork Motorcycles, Ather has managed to get funding for the initial phase of production, with Tiger Management pumping in $12 million in May 2015. The company has a manufacturing unit in Whitefield in Bangalore from where it plans to roll out 5,000 to 10,000 units in the first year. “The output is not an outcome of the market limitation but a number we would be able to comfortably handle. Since this is the first product coming from the Ather stable we want to be on top of any situation after the vehicle hits the road,” says Mehta.

As a result, Ather is also playing it safe with geographies. “We will initially start off with Bangalore and then move to Pune and Chennai. Once we are confident of our internal systems and based on customer feedback, in the next phase we will enter Delhi and Mumbai,” reveals Mehta. The company is expected to start production early next year, while shipping will begin in the second half of 2017.

The other unconventional approach that Ather is taking is to sell the S340 online. And instead of dealers, it will have experience zones. Ravneet Singh Phokela, chief business officer, says, “We will open up for pre-orders soon, through our own website. For consumers to get a touch and feel of the S340 and to test ride it, we will have experience centres.”

Also, in the build-up to the launch, Ather is taking a different route. For instance, it is holding open house events for enthusiasts, taking them through the details of the product and explaining the technology behind it, even allowing them to test ride the prototypes. “I am not aware of too many brands engaging with customers at such an early stage and have them test the trial vehicles,” says Phokela.

While the company has gone public with its specs, it has not yet revealed the price of S340. According to Mehta, the scooter will be priced between the cost of a Honda Activa (starting from Rs.60,000) and Vespa (over Rs.1 lakh). What’s interesting to note is that under the Faster Adoption and Manufacturing of Electric (Hybrid) Vehicles scheme, the government is promising buyers cash incentives ranging from Rs.1,800 to a maximum of Rs.29,000, depending on the technology. It’s quite likely that the S340 could fall in the higher bracket. Mehta, though, does not want to build in the subsidy component into his pricing estimates. “Given that we will break even only on selling 50,000 units a year, we want a sustainable price point without factoring in the subsidy. It’s necessary to set the right expectation…we do not want to create an unsustainable business,” he says.

However, with the price of lithium-ion set to fall further as more supply hits the global market, Vinayak believes the cost of lithium will continue to head south in the coming years. “Currently, lithium-ion batteries constitute a significant part of the vehicle cost, but that will change in the coming years,” feels Vinayak. In fact, the US-based National Renewable Energy Laboratory has said that only 40% of the 53 gigawatt-hours of the global lithium-ion cell production capacity in 2015 was utilised.

No dream too big

The electric two-wheelers market in India is really nascent. Besides Hero Electric, there are players like Yo Bykes, Lohia Motors and a recent debutant Ampere Vehicles. But most of the models’ specs don’t match up to the standards that Ather is creating with the S340. In fact, the number of electric two-wheeler makers in the country has fallen from 28 in FY12 to just around five players even as total electric vehicles sold plummeted from 100,000 in FY12 to 22,000 units in the previous fiscal.

While incumbents are pointing fingers at the government for not creating a conducive environment for the EV industry, Ather is staying away from the gripe lobby. “We are not even saying we are an electric scooter maker. Our USP is that our vehicles are going to be intelligent, they are going to learn from you and mould their performance around your usage pattern. There is a huge market out there if you have the right product,” says Mehta. Concurring with him is Srinivasan, who says, “Not very long ago, people were skeptical of Tesla’s success but the company overcame that by having a great product that early adopters were willing to buy. Similar, predictions were made about the hybrid market when the Toyota Prius came out. Sometimes, customers just do not know what they want until they have something placed in their hands!”

Ather is looking at an ambitious sales target of 100,000 units over the next five years. “We don’t want to grow at 10-20% but at 100%,” says Mehta. While the current manufacturing facility can be ramped up to 25,000-30,000 units at the upper end, Ather will have to build another plant to scale up their business. Srinivasan opines that the challenge for Ather is to quickly integrate experts into its team and aggressively attack the scale issue, but Professor Kumar believes Ather can get there. “This is a young team where everyone is free to talk, fight, agree, disagree, and ultimately conclude on what is right. That is what separates the boys from the men. The Heros and the Mahindras better watch out!” smiles Kumar.