In 1998, Tata Motors’ tryst with destiny in the passenger car business began with the launch of Indica. Despite all the attention, Indica failed to sizzle, with sales falling 20% the next year as customers complained that the car was rolled out despite glitches.

Tata Motors carried out a survey to identify the problems, and discovered that the components being procured from Tier 1 and Tier 2 suppliers were of sub-standard quality. Amit Bhingurde, chief operations officer, TAL Manufacturing Solutions, a Tata Motors subsidiary, explains the reason: “The manufacturers were not able to produce high-quality components as they couldn’t afford automation.”

To address the issue, TAL, a leading player in the machine tools and equipment-building industry, mulled over the idea of making a low-cost robot to help micro, small and medium enterprises (MSMEs) move up the value chain, but nothing materialised. It all changed in 2014 when Bhingurde, who had worked with Tata Motors between 1992 and 2008 and had witnessed the fall of Indica, joined TAL as its chief operating officer.

He started working on the idea of manufacturing Brabo, the first Made-in-India robot. “We decided to build a robot which could be affordable to MSMEs and cater to their requirements,” adds Bhingurde.

A team of six engineers began conceptualising the basic design. The first prototype, with 2 kg payload, was made in May 2014 and presented to the board, which gave its nod to the concept. Brabo was later showcased at several prominent events such as ‘Make in India’ and IMTEX in 2015 and 2017 respectively. “We received a lot of attention from MSME customers. So, we decided to build a line of robots,” reveals Bhingurde, who officially unveiled the robot in April 2017.

Multi-purpose and user-friendly

Manufactured at TAL factory in Pune, the robot, which can handle a payload of 2-10 kg, is priced Rs.500,000-700,000, and can be bought on monthly instalments. Bhingurde claims that it can increase productivity by 15-30% and has a payback period of two to three years.

Brabo has been built to take over dull, dirty and dangerous jobs such as welding and grinding. “No one wants to do repetitive or hazardous work. The productivity of anyone who does repetitive work will go down,” explains Bhingurde.

Kalpana B, partner and head, intelligent automation, KPMG, believes that by automating boring repetitive jobs, manual labour can focus on jobs that require them to use their skills. She adds, “Automating hazardous tasks will help eliminate worker safety issues. Therefore, robotics automation will also benefit the small and medium manufacturers.”

Brabo can also be used for a gamut of services — picking up and placing materials, assembling parts, machine and press tending. It is 50-70% cheaper compared with international robots that cost around Rs.1-1.2 million for similar payloads.

It is not only cost-effective, but also easy to use and maintain. “People don’t want to use complicated. Our USP is that our robot is easy to use, programme and maintain,” says Bhingurde.

The robot was designed to suit Indian conditions. Small firms in India face regular power outages, hence the robot was built to endure electricity fluctuations. “Brabo can operate on a single phase connection and can withstand voltage and frequency fluctuations. It is designed to operate in Indian temperature and humidity,” says Bhingurde.

Big and small customers

While Brabo is targeted at MSMEs, it’s also useful for large-scale industries such as logistics, automotive, engineering, precision machining, software testing, electronics, plastics, logistics, education and aerospace. Original equipment manufacturers (OEMs) such as Mahindra & Mahindra, Tata Motors, Bosch, John Deere and Talbros Automotive Components, too, have deployed the robot. “The big companies had earlier asked for one or two units, but subsequently, they placed multiple orders,” he says.

Small firms that have deployed the robots are happy with the productivity increase. CPG Industries, a Satara-based MSME, uses Brabo robots to manufacture components for the automobile industry. The company has deployed three robots on its shop floor. “We manufacture two-wheeler engine components for Bajaj Auto. These are critical components in terms of quality and deliveries. To achieve this, we were dependent on the workforce and it was impossible to cope up with their quality norms. So we had no option but to automate and use robotics to solve this problem,” says Ashish Gandhi, partner, CPG Industries.

Highlighting the efficiency of Brabo, he says, “It solved the problem of employee absenteeism. It brought in quality consistency and delivery. A robot can be used on any day including public holidays. What two people could complete in eight hours, a single robot took lesser time to do it. Thus, productivity and quality improved.”

Kalpana believes that with automation providing better consistency and precision, MSMEs will be able to move up the quality curve. “Typically, small and medium manufacturers are constantly battling issues such as shortage of skilled workers, rising raw material and labour costs, offshore competition, quality concerns, and worker safety issues. Robotic automation helps by freeing up manpower resources so that they can be trained and deployed for performing higher-value tasks that need skilled labour,” she says.

Built to order

TAL has a manufacturing capacity of 3,000 units. While the current utilisation is around 20%, the company expects utilisation rates to improve in the next couple of years. TAL has orders to deliver 450 units by the end of this year.

The company is currently creating robots with a maximum size of 10 kg payload and wants to increase it to carry out more significant applications such as spot welding, palletising, forging, material handling for heavy parts. “We are working on developing newer variants with higher payload capacity,” adds Bhingurde.

TAL also has a wide network of service engineers and system integrators in major hubs in India. “We ensure that service is provided within 24 hours. We keep spare parts’ stock at regional offices and have trained 30 system integrators across India. If something goes wrong, our customers can call them immediately,” says Bhingurde. The company has two regional offices in North and South India and is headquartered in Pune. Around 10 service engineers are spread across Delhi NCR, Nashik, Chennai, Bengaluru, Ahmedabad, and Belgaum.

The delivery time of the robots depends on the applications required. “If applications have to be installed in a robot for performing complicated tasks such as welding and grinding, then it may take two to three months for delivery of the robot,” says Bhingurde. He also claims that after it’s delivered, “a user with no previous experience of operating a robot can easily learn in two to three days.” Gandhi says he didn’t have to hire any new personnel to handle Brabo. “It was essential to deploy Brabo to increase quality and productivity, but you don’t need highly skilled engineers to use the robot. With little training, my existing staff has started maintaining it.”

Automation gains

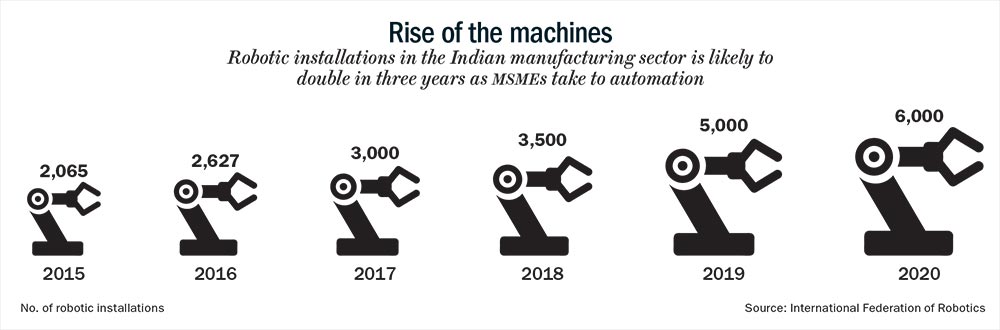

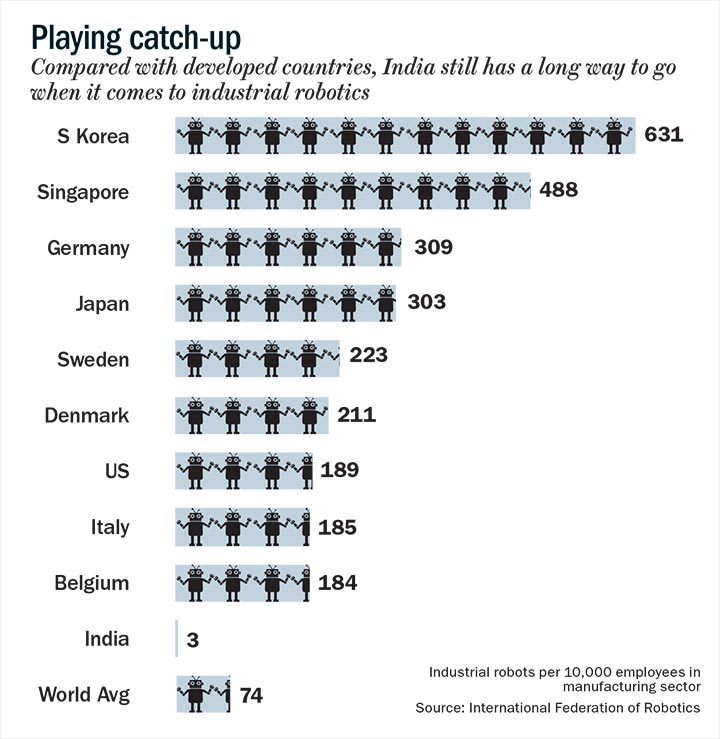

Automation, coupled with human intelligence, is changing the industrial sector. The automation of production is accelerating worldwide as 74 robots units per 10,000 employees is the average of global robot density in the manufacturing sector, according to International Federation of Robotics (IFR). South Korea tops the list with 631 robots per 10,000 employees. While Asia has an average density of 63 units per 10,000 employees, India severely lags behind with three robotic units per 10,000 employees in manufacturing sector (see: Playing catch-up). However, the IFR estimates that the robotic units will rise by 128% in India by 2020, reaching 6,000 units.

The industrial robotics market is expected to grow from $40.68 billion in 2017 to $69.14 billion by 2023, at a CAGR of 9.45%, according to MarketsandMarkets research. “The desire for speed and efficiency in operations and change in customer preferences that warrant a change in processes at a faster pace have fuelled the adoption of automation. We can say that it has the potential to outmatch other sectors,” feels Kalpana.

While India currently languishes behind the US, European and Asian countries, Bhingurde says, “The number of robots in China was remarkably less. But today they are picking up the pace. Similarly, we believe that demand for robots will go up in India as industries continue to grow.” He adds that the market for robots in some developed markets has already reached a saturation point. “The number of robots per 10,000 employees could remain the same abroad unless the industries expand. However, India has huge potential,” he says.

As Brabo continues to broaden its scope, customers are making a beeline. After receiving 267 orders in FY18, the company has already got 450 orders in the first three months of the current financial year. TAL has also managed to find customers in Europe. After acquiring CE certification in 2017, TAL has started exporting robots to Europe. “We supplied Brabo to BITS Pilani’s Dubai campus for educational purposes and recently appointed two system integrators in Europe. We are expecting orders from them soon,” says Bhingurde.

TAL is now dreaming big. It plans to provide robots to the service industry. “We will try to create applications for the service industry and make robots carry out domestic chores,” reveals Bhingurde.

Amid the growing narrative of jobs versus robots, MSMEs and OEMs looking to move up the value chain have little option but to opt for robots as their own survival is at risk in an increasingly disruptive future. That being the case, Bhingurde has very little to worry about.